Comprehensive SF6 Gas Treatment Services

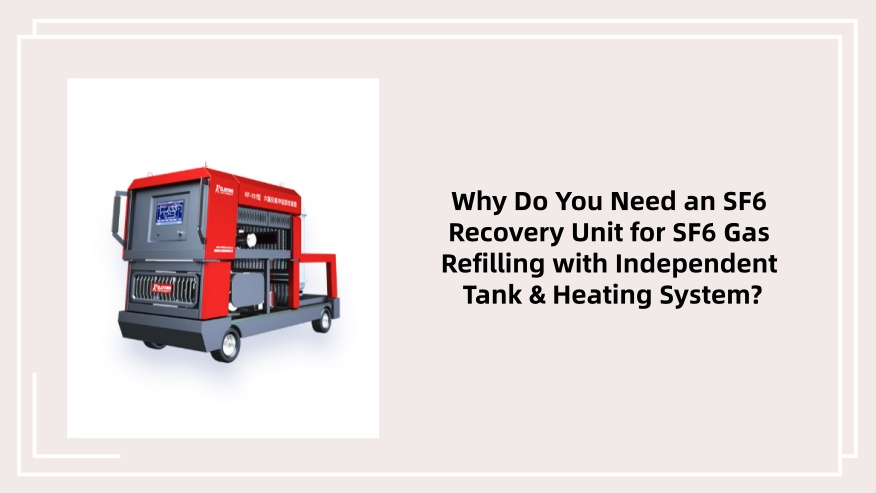

RF-300N Mobile SF6 Recovery and Purification Equipment

The RF-300N mobile SF6 recovery and purification equipment is a large-scale intelligent SF6 gas recovery and purification equipment controlled by PLC newly developed and produced by our company. It is mainly used for comprehensive gas treatment services with multiple functions such as vacuum pumping, gas recovery, gas refilling for SF6 electrical equipment and switches, gas filling into cylinders, and gas purification and regeneration.

Our Products

SF6 Gas Recovery And Purification Handling Equipment

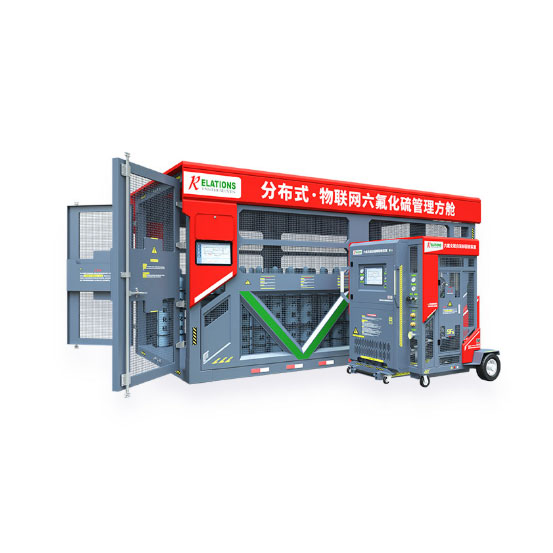

Comprehensive Operation Of Sulfur Hexafluoride

RFG-1001 Mobile SF6 Gas Service Workstation

The mobile SF6 gas workstation has the functions of high-power recovery, high-quality purification, large-capacity storage, large-flow inflation and high-speed vacuuming.

Recovery rate: 60m³/h

Negative pressure recovery rate: 160m³/h

Vacuum pumping rate: 500m³/h

Inflation rate: 150 kg/h

Why choose our SF6 equipment?

SF6 Relations combines state-of-the-art technology with the latest customer or market demands, ensuring the durability of our SF6 gas handling equipment.

Our comprehensive portfolio of service equipment enables easy, safe, and cost-effective maintenance. Whether it's maintaining medium-voltage switchgear, high-voltage switchgear, or gas-insulated lines, SF6 Relations' products are designed to improve SF6 handling efficiency.

Each product is meticulously designed to optimize efficiency and enhance safety, reflecting our commitment to zero emissions and excellent customer service. Through continuous training and support, we ensure that customers have the knowledge and tools needed to maintain high performance.